#229 - Building a Martian House - Mars Month 4

- Matt Russell

- Mar 22, 2021

- 8 min read

This week Rob joins Matt to talk about habitations on Mars. We Interview Nicki and Owen from the Building a Martian House Project based in Bristol. In a bumper episode about Mars Habitats.

“If we’re going to get to Mars, we’re going to have to clear the maps. The dragons, cyclops, and other monsters of the mind must be killed, and the siren exposed for the fraud she is.”

Robert Zubrin (The Case for Mars)

Ella Good and Nicki Kent are artists based in Bristol, UK. and Owen Pearce is an architect who has been involved in the project.

In 2014 Ella and Nicki started a ten year series about Mars, Earth and the future. They’re making lots of projects exploring different aspects of what going to Mars might make people think about - from imagining a whole new society to sustainable living here on Earth. Have a look around their website to see how you can get involved in our current project.

Rob Annable - The Spodcat concept!

Architect at Axis Design Architects Ltd

How do we build a city on Mars?

So all the same things matter on Mars as they do on the moon,

radiation protection,

lack of gravity,

poisonous regolith,

extreme cold,

energy, except now there is no rescue - no easy way back and no easy way there.

I think it’s fairly obvious we got to practice this stuff on the moon first, I just can’t see a habitat on mars for 20 or 30 years at very best.

So all the same things matter on Mars, radiation protection, lack of gravity, poisonous regolith, extreme cold, energy, except now there is no rescue no easy way back and no easy way there.

But probably the most interesting study when it comes to habitats was done with NASA’s and Bradley University 3D-Printed Habitat Challenge with sponsors including merch genius’ Caterpillar. , one of the NASA 2005 Centennial Challanges

The multi-phase challenge is designed to advance the construction technology needed to create sustainable housing solutions for Earth and beyond

Had $3.15million up for grabs.

Phase 1, the Design Competition, required teams to submit architectural renderings and was completed in 2015. ($50,000 prize purse) Winner ICE HOUSE

Phase 2, the Structural Member Competition, focused on material technologies, requiring teams to create structural components. It was completed in 2017. ($1.1 million prize purse)

Phase 3 , the On-Site Habitat Competition, challenges competitors to fabricate sub-scale habitats, and has five levels of competition – three construction levels and two virtual levels. For the virtual levels, teams must use Building Information Modeling software to design a habitat that combines allowances for both the structure and systems it must contain. The construction levels challenge the teams to autonomously 3D-print elements of the habitat, culminating with a one-third-scale printed habitat for the final level. ($2 million prize purse)

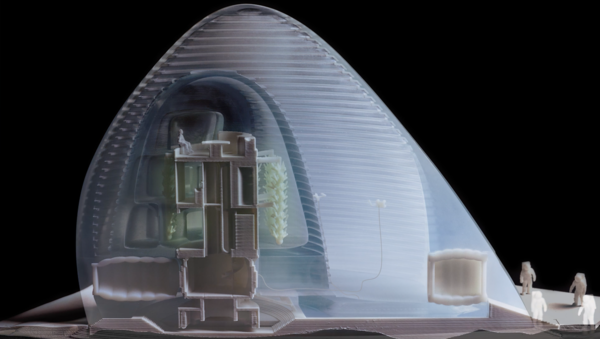

2015: In Phase 1 the winner was Team Space Exploration Architecture and Clouds Architecture Office of New York, New York, for their design, Mars Ice House.

Located in the Alba Mons in the Northern Hemisphere, where there should be an abundance of water covered by 30cm of loose regolith!

Their design is very clever, normally the habitats are buried beneath the perchlorate rich regolith, but this one is proudly on the surface, calculating that only a 5cm ice shell can protect against the radiation. Basically, ice is brilliant at stopping radiation while allowing natural light through. Ice possess tensile properties (~2-3 MPa)10 that is, in fact, superior to materials such as brick

With lots of natural light! robotic printing of the shell’s surface to create a “Fresnel lens” effect, refracting and concentrating the light within the interior surface of the domed structure

large ETFE inflatable windows filled with radiation shielding gas further expand the perceived volume and frame views into the landscape.

It’s likely that the “transit habitat” will be many floors vertical stack so, so is the Ice House to assist in orientation and life on the red planet.

The ice shell is a series of onion layered domes enclosed by a Dyneema reinforced ETFE membrane (like the Eden Project domes in fact)

The outer shell will have the “front yard in it” so will feel like an outside space with then need for a spacesuit.

Environmental Control and Life Support System (ECLSS) vent into the interior volume.

The Hydroponics surround the living quarters and the excess oxygen is vented into the front yard section

Water is collected in its gaseous phase (pressure on Mars completely changes how water behaves) and spayed in water form from the 3d printing nozzle, where it becomes ice and starts printing the structure. AS the interior is under the same pressure as the Shuttle interior 70kPa

Aerogel is 3d printed into the gap between Ice shell and inner quarters.

The Robots involved

iBo: triple nozzled to print water, fibre and Aerogel in layered rings. It can make and climb the wall as it goes, by printing the ridges that it clings to.

WaSiBo: this robot is lowered through the base airlock of the lander into the Martian environment. Once outside, WaSiBo operates in two modes: Foundation-Sinter Mode and Water-Mining Mode. Both modes use the same basic processes, heat/pressure and excavation enabling them to be engineered into a single package

Deployment!

Take off designed for Falcon Heavy or SLS

The Ice house lands on the surface, in the process the thrusters will actually excavate the surface exposing the ice underneath just like MArs Phoenix did in 2008!!

Wasibo drop, deployed to mine subsurface ice and build a new foundation

reservoir and hose deploy, the clever way that Wasibo uses phase change physics on the moon means it can keep the dust out of the system and build a reservoir of water for the ice house really efficiently.

Wasibo starts sintering the habitat foundation,

Inflates the ETFE membrane precision made on earth

deploys airlocks also integrated and precision made on earth

prints the ice, (fibrous silica is added to make it even stronger and longer-lasting)

Prints the inner shells, from Aerogel that insulates the ice so it doesn’t melt and the interior can be warm.

Grows plants,

crew arrive.

2017 Phase 2 The agency awarded first place and a prize of $250,000 to Team Foster + Partners | Branch Technology of Chattanooga, Tennessee, for successfully completing Phase 2, their innovative materials and structure was the strongest.

May 2019 Phase 3

After 30 hours of 3D printing over four days of head-to-head competition, NASA and partner Bradley University of Peoria, Illinois, have awarded $700,000 to two teams in the final round of the 3D-Printed Habitat Challenge. The top prize of $500,000 was awarded to New York-based AI. SpaceFactory. Second-place and $200,000 was awarded to Pennsylvania State University of University Park, The habitats were constructed in 10-hour increments in front of a panel of judges. Once the printing was complete, the structures were subjected to several tests and evaluated for material mix, leakage, durability and strength.

AI Space factory design! MARSHA - In an alien environment 54.6 million kilometres away, construction and materials must be rethought entirely

Where structures on Earth are designed primarily for gravity and wind, Martian conditions require a structure optimized to handle internal atmospheric pressure and thermal stresses

Just like the ICE house, the outer shell is an external front yard type environment that takes all the strain and pressure and the interior can be light and made for human habitation in mind.

THEIR FORMULA FOR 3D-PRINTING ON MARS

In collaboration with Techmer PM, they are formulating an innovative mixture of basalt fibre extracted from Martian rock and renewable bioplastic (polylactic acid, or PLA) processed from plants grown on Mars.

Both PLA and Basalt fibre has excellent qualities, hence these peeps won the prize.

Basalt is as strong as Kevlar

Plastic shield radiation, is reusable, like basalt doesn’t expand when heated, is non-toxic and non-conductive.

The cylinder shape is the best shape

Very effective pressure vessel

Great floor area to surface area ratio (less surface area the less material under lower stresses, so less resource you need to build!)

Great Usable floor area to volume and diameter ratio (less volume reduces mechanical loads on systems, and reducing diameter reduces structural stresses))

Easier to divide the areas of work by level

The most printable pressure vessel

A smaller footprint decreases the need for such a big mobility range of the printer!

Water filled skylight!

The updated design includes internal clamps with integrated sliding expansion plates

The windows are designed like cupula windows on the iss.

All the airlocks and windows would be manufactured on earth, with magnetic louvres.

Located in "Cydonia Mensae" mild north climate with year-round sunlight, with subsurface ice, ISRU abundance. The low elevation gives slightly better radiation protection.

Mars Society!!!

“...an international contest for the best design plan of a Mars city-state of 1,000,000 people… should be self-supporting to the maximum extent possible – i.e. relying on a minimum mass of imports from Earth…"

It is not necessary that the city-state be built all in one location on the Martian surface. It can be done that way or one or more central cities can be set up, supported by outlying bases on Mars or its moons, as needed.”

In scoring city-state designs, points will be allocated on the following basis:

30 points technical design

30 points economic

20 points social/cultural/political

20 points aesthetic

...the contest received a total of 175 team applications from over a dozen countries… Top 5 entries presented their proposals at the Mars Society conference in October 2020 with 1st place awarded to the Nexus Aurora multi-national project…

-------------------------------

Spodcat concept!

“Isotropic planning for resilience and equality, a distributed network of Martian archipelagos.

or

How to make civic space in a world that has no Breathable Commons”

A project concept that focuses on the question of common, shared space and how to ensure it is a safe, resilient infrastructure that all depend upon equally and can enjoy without hindrance. The references seek to turn to terrestrial architecture and urban design theory for inspiration - considering how our notion of the city is reconfigured in a harsh environment with little atmosphere.

The concept imagines a city-state formed from 1000 landing sites, settled by 3 communities at each site forming their own territories from the landing pad, dwelling space and food production spaces, then completing the archipelago by the formation of common space between each community… resilience and interdependency is then formed through agreement by 3 stakeholders to feed and pressurize the common space.

(see the Nolli map: Giambattista Nolli)

This concept is repeated across the landscape, forming a non-hierarchical horizontal city inspired by Erich Gloeden’s urban design concepts of equal settlements forming a distributed network - with the space between the cells joined further to become the commons targeted for terraforming, creating the civic space that every city needs.

Rough concept available on Google docs plus background notes - comments welcome!

Winning entry - Nexus Aurora

An open-source project with a large multi-national team - 50+ members, 100 pages of technical reports, 5Gb of renders and models, 60k group messages

Imagines an industrial base providing a foundry for materials to future interplanetary settlers - arguing tourism alone as an economy is unrealistic.

Aspires to a communitarian society acknowledging the joint role of independent cities and the state, with the recognition that settlers can enjoy rights to welfare through a Martian version of UBI that could include shelter, food and air.

Living proposals that 'reject the concept of cities built of tunnels and underground habitation' and hold on to the value of sunlight and walking in community spaces.

Extracts from the report:

Preparation/landing

Site: Eastern rim of Hellas Planitia - access to glaciers, range of minerals, more atmosphere to travel through because of low level

First buildings simple cylindrical pressure vessel with steel end domes and reinforcing rings - Basalt Fibre Reinforced Plastic in-situ manufacture woven into clear polymers.

Necessities

Commitment to solar - thin-film CIGS cells rolled out across landscape - no dependence on the geopolitics of launching nuclear fuel…

EVA suits aiming at ease of manufacture and repair - a partial pressure suit for 8 hours use of the type worn by fighter pilots

Modular robotic platform - open-source design, multiple uses

Production + Industry

Commitment to extensive greenhouses instead of artificially lit - calculating that it takes 200-600 kWh/m2 vs 800 kWh for artificial

Structures

‘570 habs’ of 570 people within 5m thick walls of rammed regolith, with a roof covered with 3m of water for radiation shielding - each forming the equivalent of an urban block. Increased in size further with combinations forming ‘Air Mattresses’ + 200m domed spaces within natural crater formations.

Proposal for landmarks - a monument for Fallen Wanderers, large infrared telescopes and the Tree of Life - a giant Redwood tree planted on day 1

Urban Planning

Based on Ebeneezer Howard’s Garden City concept - distributed small towns of mixed employment - each node organised around a central open space in a crater

Transport - 6m diameter service tubes - walkable routes + robots and services - larger boulevards for longer distances

NFC cards for controlling access to particular zones

Economics

A welfare state of ‘pseudo-UBI’ providing life support and basic food to prevent dystopian ‘oxygen fees apply’ scenarios.

Comments